PRODUCT FINDER

Which products are best for you?

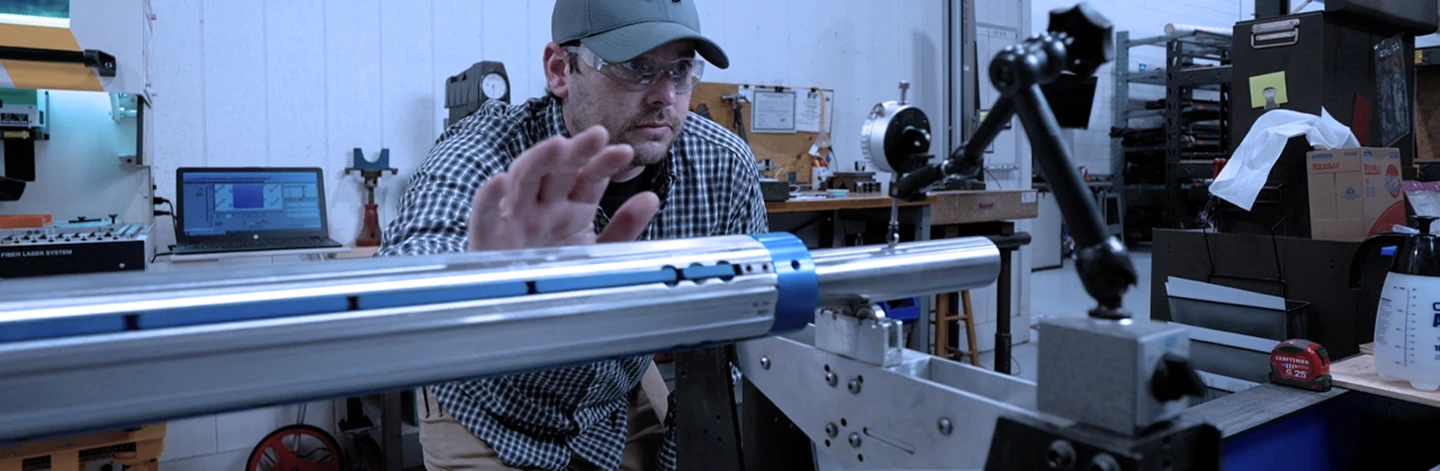

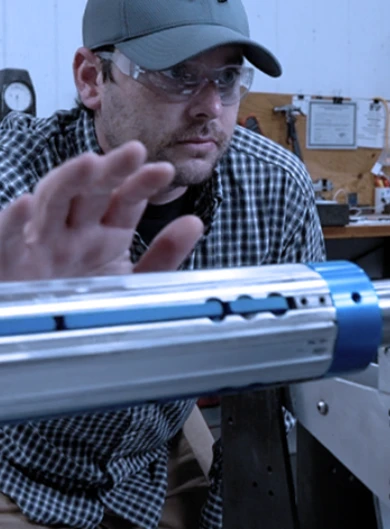

DF-1000 Torque-Activated Chucking System

Quick & easy roll changes without tools, air, or keys for three-inch core applications. Ideally suited for Goss Community presses.

Product Info

DF-1000 Torque-Activated Chucking System - Important Characteristics

Quick & easy roll changes without tools, air, or keys for three-inch core applications. Ideally suited for Goss Community presses.

Quick & easy roll changes without tools, air, or keys for three-inch core applications. Ideally suited for Goss Community presses.

DF-1000 Core Chuck System Components

DF-1000 Synopsis

The Double E Company’s DF–1000 “Quick–Change” Core Chuck Assembly replaces outdated, heavy, or labor intensive chucking systems. It replaces knock-in cones or wedges, manually operated chucks, and heavy through shafts.

The DF–1000 is a torque activated core chuck which engages automatically

when the roll starts to turn. As more torque is applied, the chuck

grips harder – there is no need for operator adjustment. The chuck works

the same way in either direction of rotation, and does not require any

air to function.

The DF–1000 is easy to use – just slide the assembly into the core.

That’s it. And when the roll has expired, just slide a piece of core

over the collar to retract the fingers, then slide the whole unit out of

the roll. No tools are needed to change rolls.

Inside the chuck, six precision-ground solid steel rollers travel up and

down cams on the central hex and the backs of the jaws. This rolling

action causes the jaws to expand in order to grip the core. The rollers

drastically reduce friction inside the chuck, minimizing wear on the

internal components. Consequently, the DF–1000 requires very little, if

any, maintenance.

The jaws are designed to grip the core without damaging it. They are

held in place by two heavy-duty springs which also aid in jaw

retraction. Reliable jaw retraction means the chuck never gets stuck in

cores like cones or wedges often do. The chuck’s performance is enhanced

by a unique roll collar which supports the roll at the end opposite the

chuck. Once the assembly is inserted into a roll, the collar’s

retractable fingers snap into place to keep the roll in position and

properly aligned. These fingers are designed to retract easily when a

small piece of core is pushed over them. Once the fingers are retracted,

the assembly slides out effortlessly, ready for the next roll.

The roll collar and chuck can be mounted onto your existing through

shaft, but for high strength and light weight, nothing compares to

a Double E Dura–Light carbon fiber through shaft.

The chucking system is a perfect addition to Goss Community presses and other newspaper printing presses.

Which products are best for you?

Back to Top