PRODUCT FINDER

Which products are best for you?

DF-2000 Torque-Activated Core Chuck

Automatic Concentric Expansion

As the torque chuck expands to grip a core, it automatically lifts and centers the roll, eliminating roll bounce and vibration.

No Lubrication ~ Minimal Maintenance

Little dust accumulation in the chuck means no jamming and easy removal of cores

No Sidearm Force Needed from the Roll Stand, Multiple Core Re-Use, Elimination of End-of-Roll Waste

The DF-2000 chuck grips harder as more torque is applied. Other chucks rely on sidearm force from the roll stand to push the gripping elements into the core wall. These chucks damage the core and waste material at the end of the roll.

| FEATURE | ADVANTAGE | BENEFIT |

|---|---|---|

Smooth Gripping Jaws |

Interior wall of core is not damaged.Serrations are not used so dust is not created | Multiple core reuseNo maintenance or jamming, no contamination. |

Torque Activation |

Extreme sidearm force not necessary | Less core distortion and no end of roll wasteRolls won't bowLess roll stand fatigue; extended roll life |

Patented Roller Design |

Reliable grip regardless of torque magnitudeTrue concentric expansionLubrication isn’t needed; dust won’t accumulateLittle friction inside chuck; less wear on partsWide range of expansion | Run heavy and/or light rolls with any tensionRoll bounce is minimized or eliminatedEasier to control web tensionNo jamming; chuck won’t get stuck in coresLittle, if any, maintenance and longer chuck lifeRun butt rolls and rolls with core inconsistencies |

Step Chuck |

Single chuck can run various core sizes | Roll changes are effortless; even between sizes |

Quick Disconnect Chuck |

Interchangeable chucks mount to same plate on machines with width limitations |

One center bolt allows quick change to various core size |

Product Information

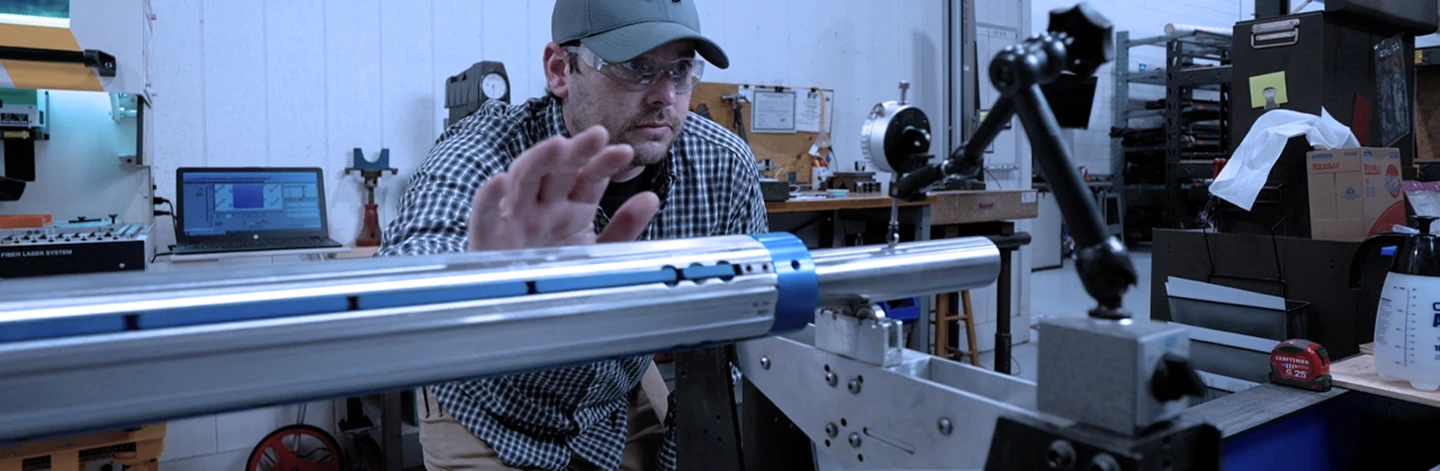

The Double E DF-2000 Torque-Activated Core Chuck

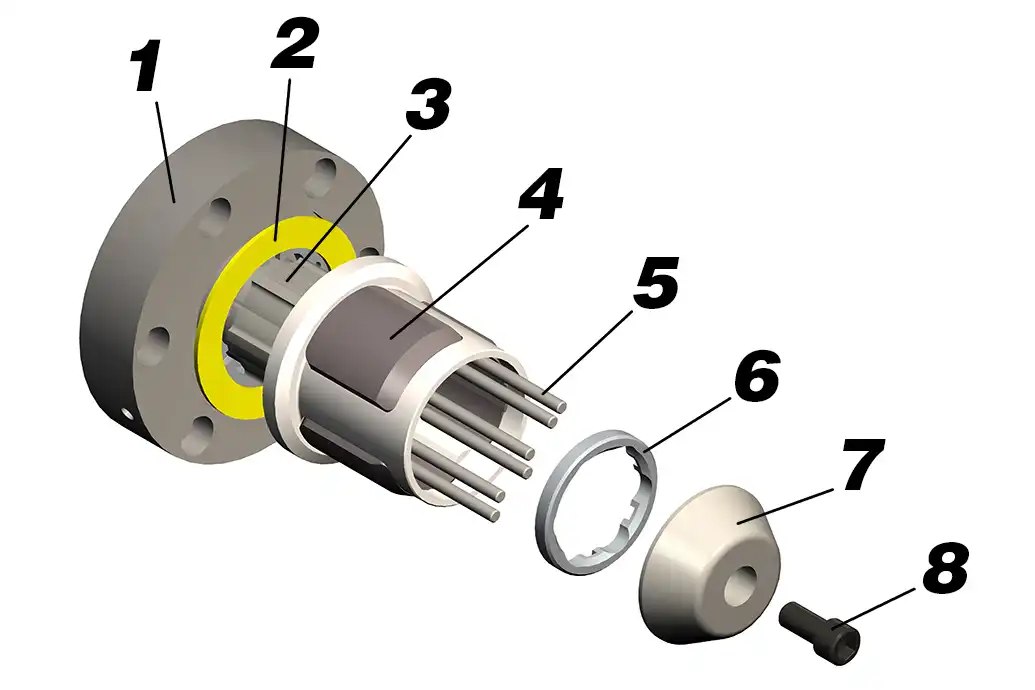

Double E's DF-2000's patented torque-activated shaftless design has made it the world's most effective and best-selling shaftless core chuck. Six precision-ground steel rollers are mechanically linked to travel up and down bi-directional ramps created by the back of the jaws and the hexagonal cam. This rolling action minimizes friction while causing expansion and retraction of the chuck’s jaws.

As a result, the chuck can be used in the lightest to heaviest tension applications. The chuck’s mechanical design eliminates the need for the sophisticated and expensive plumbing associated with pneumatic or hydraulic chucks. Rotary unions are also unnecessary with the DF–2000.

There are other chucks which are based on the torque-activated principle, but they use “sliding friction” inside the chuck for expansion. These chucks can’t overcome the friction created by the roll weight to lift and center the roll. A non-centering action results, causing roll bounce and possible jamming. Furthermore, their serrated jaws damage cores and create dust, leading to higher maintenance and more downtime.

DF-2000 "Extreme" Core Chuck

DF-2000 Step Torque Chucks

DF-2000 Quick Disconnect Torque Chucks

DF-2000 Slide-On Chuck Adapters

DF-2000 Core Kicker Chucks

DF-2000 Through-Shaft Torque Chucks

Which products are best for you?

Back to Top