PRODUCT FINDER

Which products are best for you?

Carbon Fiber Expanding Lug Shafts

Lightweight carbon fiber core shafts minimize shaft weight in unwind and rewind converting applications.

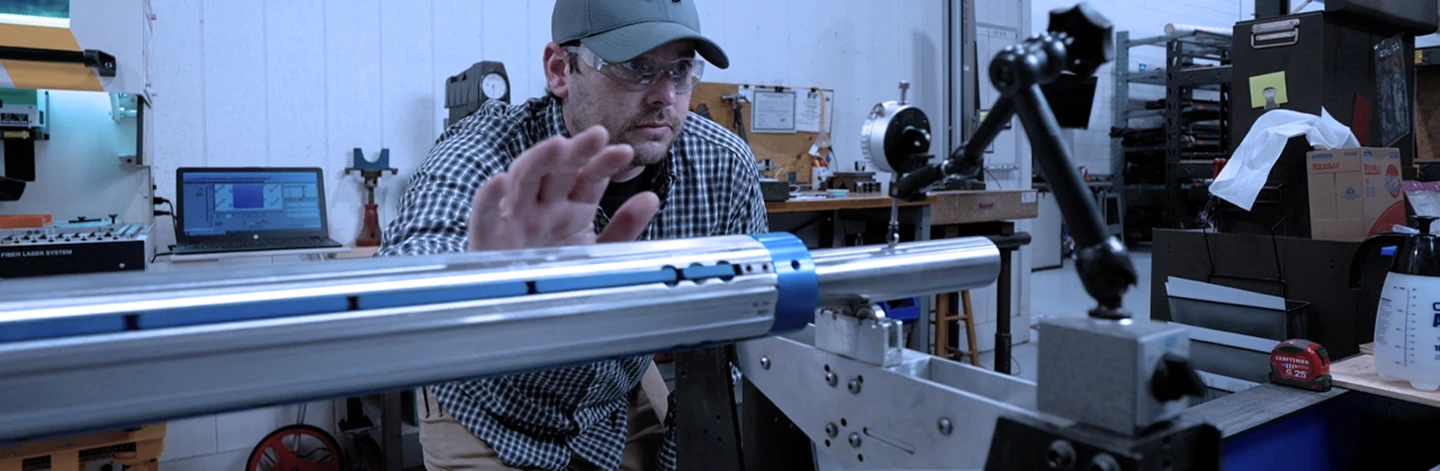

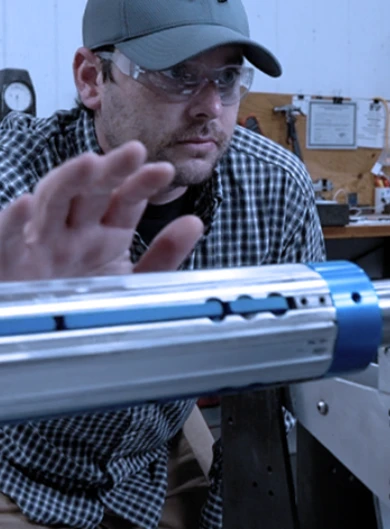

DLB-2000 Carbon Fiber Core Shafts

Lightweight carbon fiber core shafts minimize shaft weight in unwind and rewind converting applications.

DLB-2000 Carbon Fiber Core Shafts - Features, Advantages and Benefits

| FEATURE | ADVANTAGE | BENEFIT |

|---|---|---|

| Carbon Fiber Shaft Housing | Lightweight | Fewer shaft handling injuries lower worker’s compensation expenses and non-productive time. Meet regulations for single person lifting. |

| Better ergonomics | No maintenance or jamming, no contamination. | |

| Less deflection | Reduced vibration and less roll bounce. Heavier roll weights. | |

| Higher critical speed | More throughput. | |

| Protective Outer Sleeve | Protects carbon fiber shaft from abrasion. | Longer carbon fiber shaft life. |

| Proprietary Bladder | Stretches less than traditional rubber. | Dependable lug collapse ensures consistent, easy removal of shaft from spent cores |

| More resistant to heat, puncture, and abrasion. | Far less bladder failure and minimized maintenance. | |

| Springless Lugs | No springs to break and puncture bladder. | Longer bladder life; less maintenance |

| Diamond pattern gripping surface with large surface area | Better grip with less slipping. | |

| Custom Journals | No press fit facilitates journal removal. | Bladder replacement, though rare, is quick and easy. |

DLB-2000 Carbon Fiber Shaft Components

CF-1000 Dura-Light Non-Expanding Carbon Fiber Shafts (Through Shafts)

Dura-Light Mechanical Carbon Fiber Expanding Lug Shafts

Which products are best for you?

Back to Top