For more info on this product, check out the following pages:

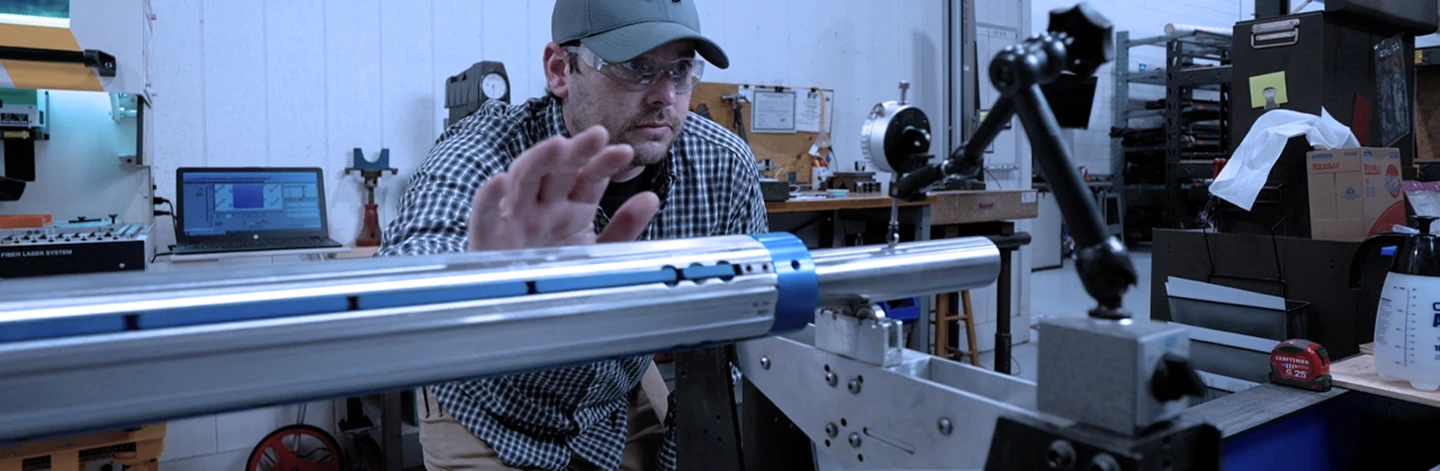

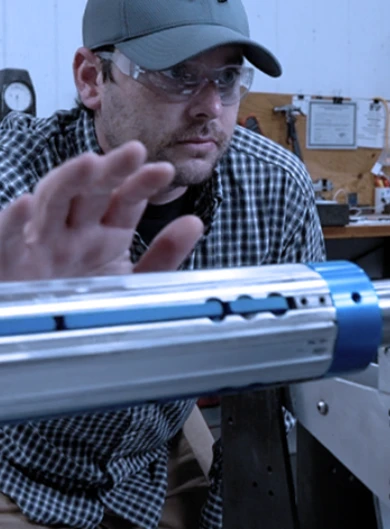

Carbon Fiber Expanding Lug Shafts

Lightweight carbon fiber core shafts minimize shaft weight in unwind and rewind converting applications.

Lightweight carbon fiber core shafts minimize shaft weight in unwind and rewind converting applications.

DLB-2000 Carbon Fiber Core Shafts - Features, Advantages and Benefits

| FEATURE | ADVANTAGE | BENEFIT |

|---|---|---|

| Carbon Fiber Shaft Housing | Lightweight | Fewer shaft handling injuries lower worker’s compensation expenses and non-productive time Meet regulations for single person lifting |

| Better ergonomics | No maintenance or jamming, no contamination | |

| Less deflection | Reduced vibration and less roll bounce Heavier roll weights | |

| Higher critical speed | More throughput | |

| Protective Outer Sleeve | Protects carbon fiber shaft from abrasion | Longer carbon fiber shaft life |

| Proprietary Bladder | Stretches less than traditional rubber | Dependable lug collapse ensures consistent, easy removal of shaft from spent cores |

| More resistant to heat, puncture, & abrasion | Far less bladder failure and minimized maintenance | |

| Springless Lugs | No springs to break and puncture bladder | Longer bladder life; less maintenance |

| Diamond pattern gripping surface with large surface area | Better grip with less slipping | |

| Custom Journals | No press fit facilitates journal removal | Bladder replacement, though rare, is quick and easy |

DLB-2000 Carbon Fiber Shaft Components

CF-1000 Dura-Light Non-Expanding Carbon Fiber Shafts (Through Shafts)

Dura-Light Mechanical Carbon Fiber Expanding Lug Shafts

Which products are best for you?

Back to Top