Manufacturers are no stranger to potential occupational hazards. Particularly in the converting industry, air shaft operators are frequently faced with the potential risk that comes with inflating and deflating air shafts. Many operators are accustomed to deflating by hand, putting their fingers at risk while facing pressures up to 100 psi.

To avoid the risk of injury, many converting manufacturers are turning to air shaft inflation/deflation tools. The inherent issue that they run into is that the majority of air shaft inflation/deflation tools have a slow flow rate and don’t integrate seamlessly with their brand of air shaft.

With the SafeInflate (patent pending), DoubleE has found the perfect solution to help converters streamline their operations while reducing potential risk to operators and their equipment. Let’s take a closer look at the potential safety hazards currently facing air shaft operators and how the SafeInflate solves those unique challenges.

Potential Safety Hazards When Inflating and Deflating Air Shafts

While quality air shafts are able to run with little to no interference during operation, there will come a time when an operator will need to deflate and reinflate the air shaft when processing new rolls of material. When doing so, many operators will use their hand to create a pinch point near the valve to remove the high-density air inside the shaft.

This may seem like an effective way to deflate the air shaft, but the process presents risk as the operator will be putting their hands in the way of air being released at 100 psi. Additionally, its common for a separate team member to pull the air shaft out of the old roll of material at the same time the operator is deflating the shaft. This has the potential to creat a scissor-like effect that can seriously wound the operator. The liability and risk of injury to both the air shaft operator and equipment is too great – which is why many converters turn to air shaft inflation and deflation tools.

SafeInflate: The Air Shaft Inflation Tool Focused on Safety

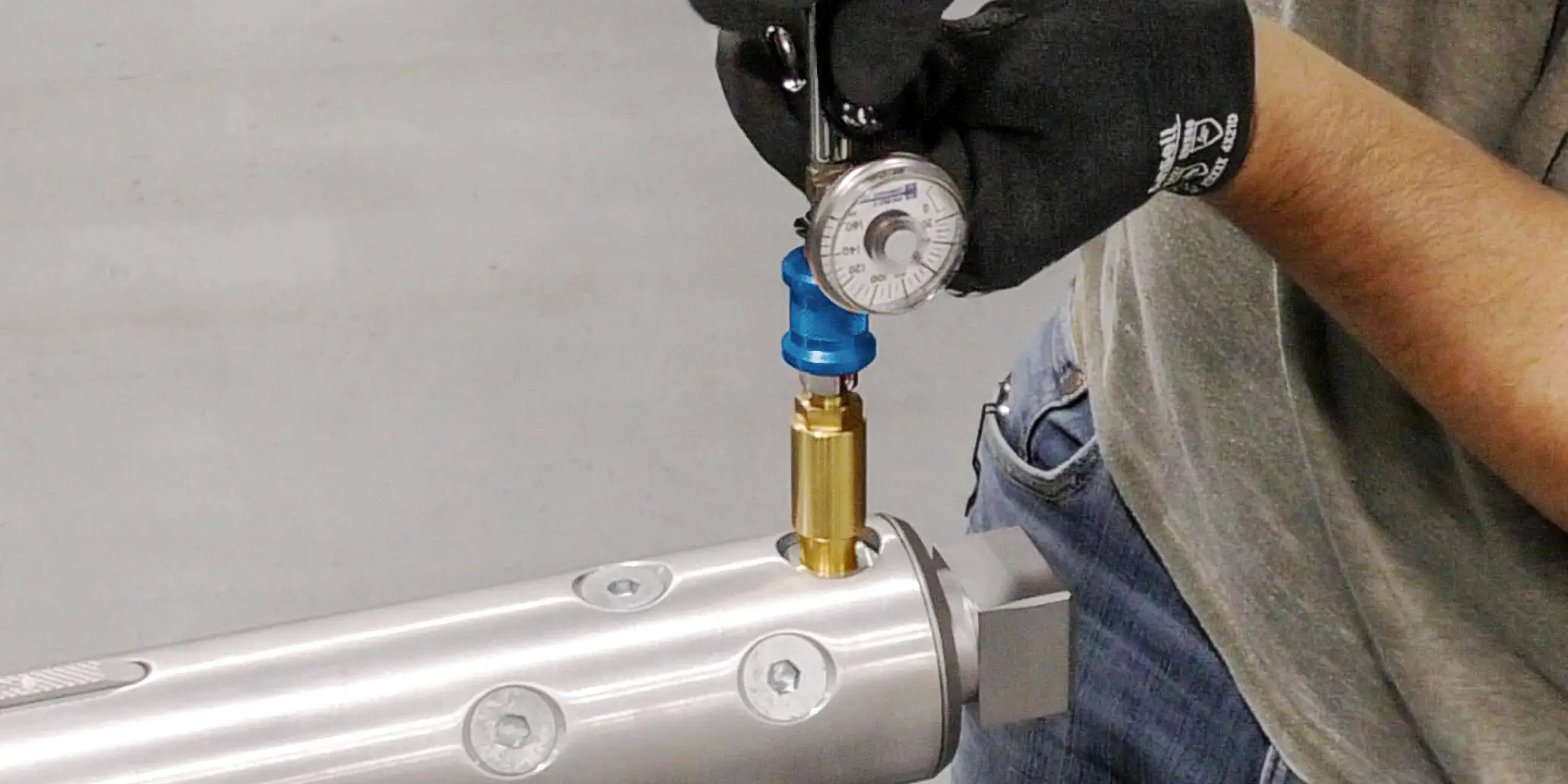

To help converters reduce risk and streamline efficiency, DoubleE created the SafeInflate, a hands-free tool that inflates and deflates air shafts at a faster flow rate than similar tools on the market.

The SafeInflate is a critical tool to prevent operator injury, completely preventing manual hand deflation. The key to SafeInflate’s safety is its innovative valve cover and air dispersal mechanism. Once the easy-to-install valve cover is in place, potentially hazardous valve indents and recesses are covered – removing dangerous pinch points for finger tips.

The air shaft or other device can then be safety deflated with the SafeInflate air gun’s air dispersal mechanism which safely deflects the highly pressurized air away from the operator’s face and eyes. Once the air shaft is ready to return to operation, it can be safely inflated using the SafeInflate air gun.

For a more detailed look at how the SafeInflate can improve the safety of your operation, check out this tutorial video.

Protect Your Operators and Equipment with Double E

Engineered specifically for the converting industry, SafeInflate (patent pending) enables operation and production personnel to inflate and deflate air shafts, pneumatic mechanical chucks, and similar equipment easily and safely.

If you’re looking to improve the overall safety of your valuable team members and equipment, consider the SafeInflate. This essential tool fits retroactively with all DoubleE air shafts, making it a seamless fit for your converting operation.

With over 50 years of industry experience, Double E has the capabilities to help solve your unique converting challenges. New challenges present themselves daily – Double E is ready to meet those challenges and create the right solution for you. Contact us today to learn more about SafeInflate and how Double E can streamline your operations and keep your machines up and running smoothly