PRODUCT FINDER

Which products are best for you?

Pneumatic Brakes for Unwind Stands

Pneumatic friction brakes used to control tension on an unwinding roll.

The Double E Group supplies a complete line of pneumatic brakes.

Ideal for corrugators, paper sheeters, and many other converting machines.

Pneumatic friction brakes used to control tension on an unwinding roll.

The Double E Group supplies a complete line of pneumatic brakes.

Ideal for corrugators, paper sheeters, and many other converting machines.

Double E Group pneumatic brakes run cool and quiet on unwind stands so brake pads last far longer than competitor's brake pads.

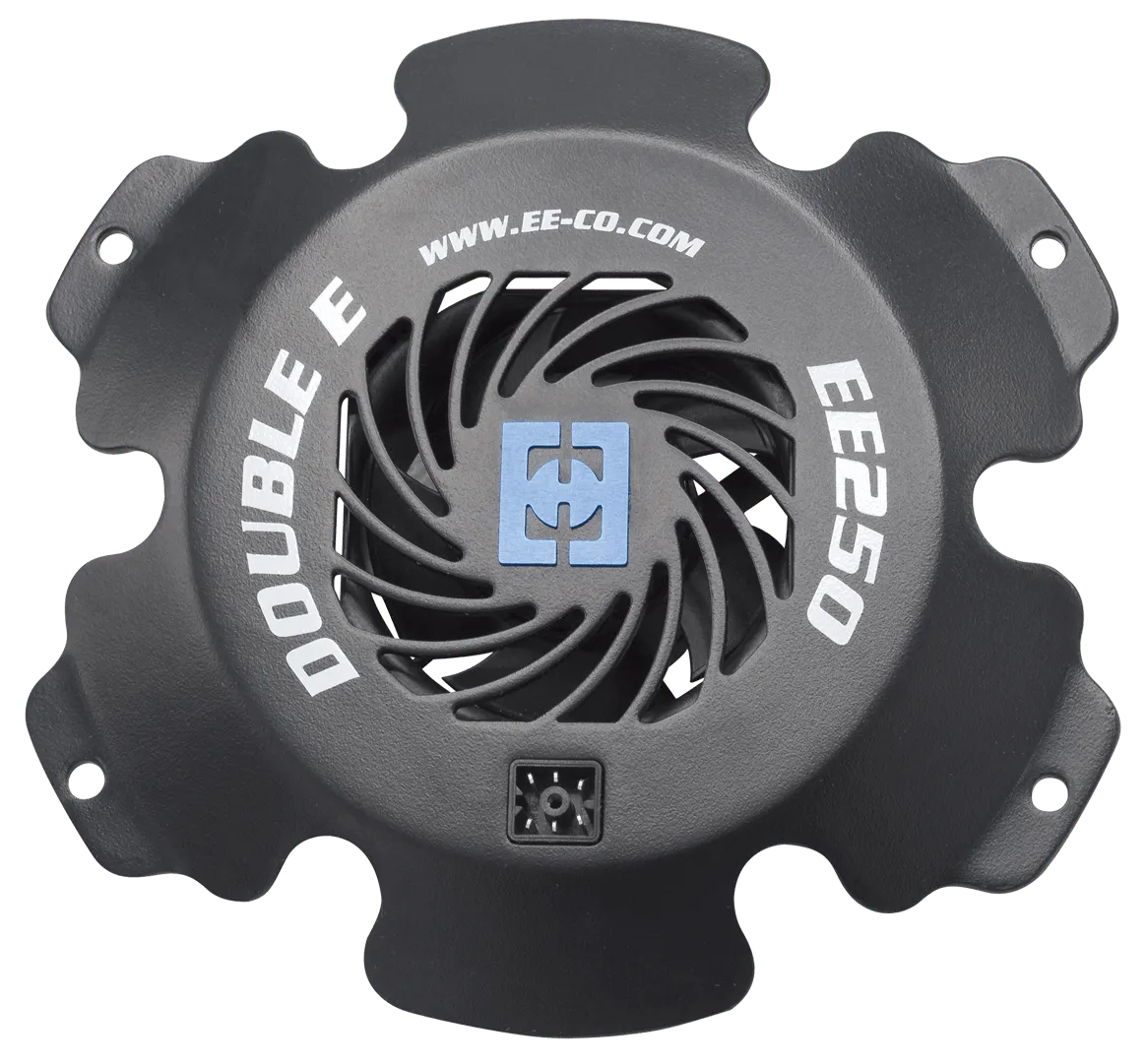

EE250 Brakes

Important characteristics of Double E Group brakes

Modular caliper design and unique turbine rotor reduce brake size & cost.

Universal High-Performance Fan Kit

Universal High-Performance Fan Kit is an upgrade for standard brakes. It is available for existing brakes already in service, as well as on new brakes.

Brake Components

Double E Group Brakes - Synopsis

The primary function of brakes is to convert mechanical energy into heat, which is then dissipated into the atmosphere. Traditional air-cooled disc brakes are actually very poor heat exchangers, depending largely on a high rotational speed, a large disc diameter, and a large radiant surface to dissipate heat. Often, these brakes overheat, reducing the brake’s efficiency while increasing noise and dust. To solve this problem, most brake manufacturers simply increase the disc size, creating an unnecessarily large brake.

Double E Group brake rotors are designed with a bi-directional design that increases airflow through the brake, even at slow speeds. This airflow allows the brake to dissipate heat more efficiently than other disc brakes.

Attention to ventilation is carried through to the brake housing as well. Double E Group brake housings use a ventilating hole pattern that permits free circulation of air from the middle of the unit to the edges. A built-in fan increases the heat dissipation even further, and ensures a cool-running brake regardless of the running speed. Because these brakes run cool, they eliminate brake fade, excessive noise (squealing) and brake dust, and premature pad wear.

Double E Group pneumatic brake pads last far longer than other brake pads because of the brake’s efficiency and the proprietary pad material. These advantages have make the Double E Group brake an optimum choice for braking converting applications.

The Double E Group brake’s modular caliper design allows flexibility with the number of calipers used (for improved tension control and/or to allow emergency stopping ability). Unneeded braking power is eliminated, and all customers get brakes that are optimized for their application.

It’s easy to upgrade any roll stand to Double E Group brakes. Most often our brakes are smaller than existing pneumatic brakes, and the basic model is appropriate and simple to install. Standard rollstand-specific models also exist for Langston, Martin, and other common unwind stands.

Which products are best for you?

Back to Top