For more info on this product, check out the following pages:

Lift and Turn

Hoist Based Roll Handling – Lift And Turn

Double E Group's hoist based, Lift and Turn Roll Handler products provide ease-of-use, superior performance and high quality. The Double E Group Lift and Turn Roll Handler features a universal mandrel holder for quick and easy changes between core sizes, and an adjustable turner arm for accommodating a wide range of roll widths.

Double E Group Lift and Turn Roll Handlers are available in a variety of models, including manual, pneumatic, and electric powered, offering a variety of ways to lift and turn rolls or rolled materials safely and easily.

Operator safety is critical and Double E Group Lift and Turn Roll Handlers are designed to maximize it. All of Double E Group's Lift and Turn Roll Handlers include safety features to lock the roll in the horizontal or vertical position and use a positive gripping surface to secure the roll.

Double E Group hoist-based roll Lift and Turn Roll Handlers are typically used for:

Double E Group also offers flexibility in its Lift and Turn Roll Handlers to meet application challenges including:

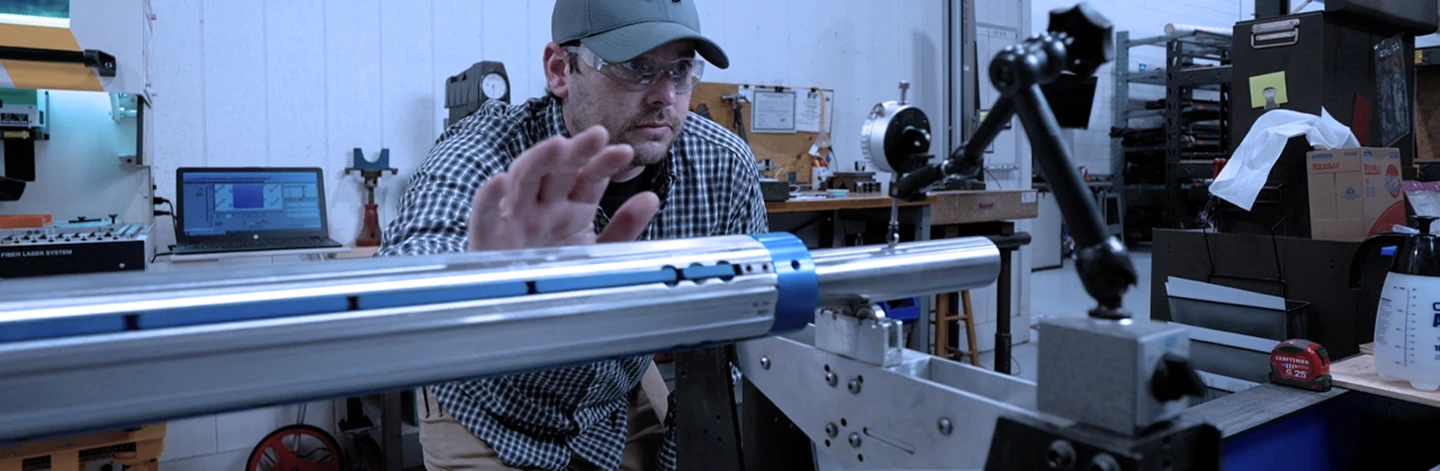

Designed and manufactured by Double E Group's world class team in Portland, Maine, Double E Group is here to become your turnkey roll handling and processing supplier!

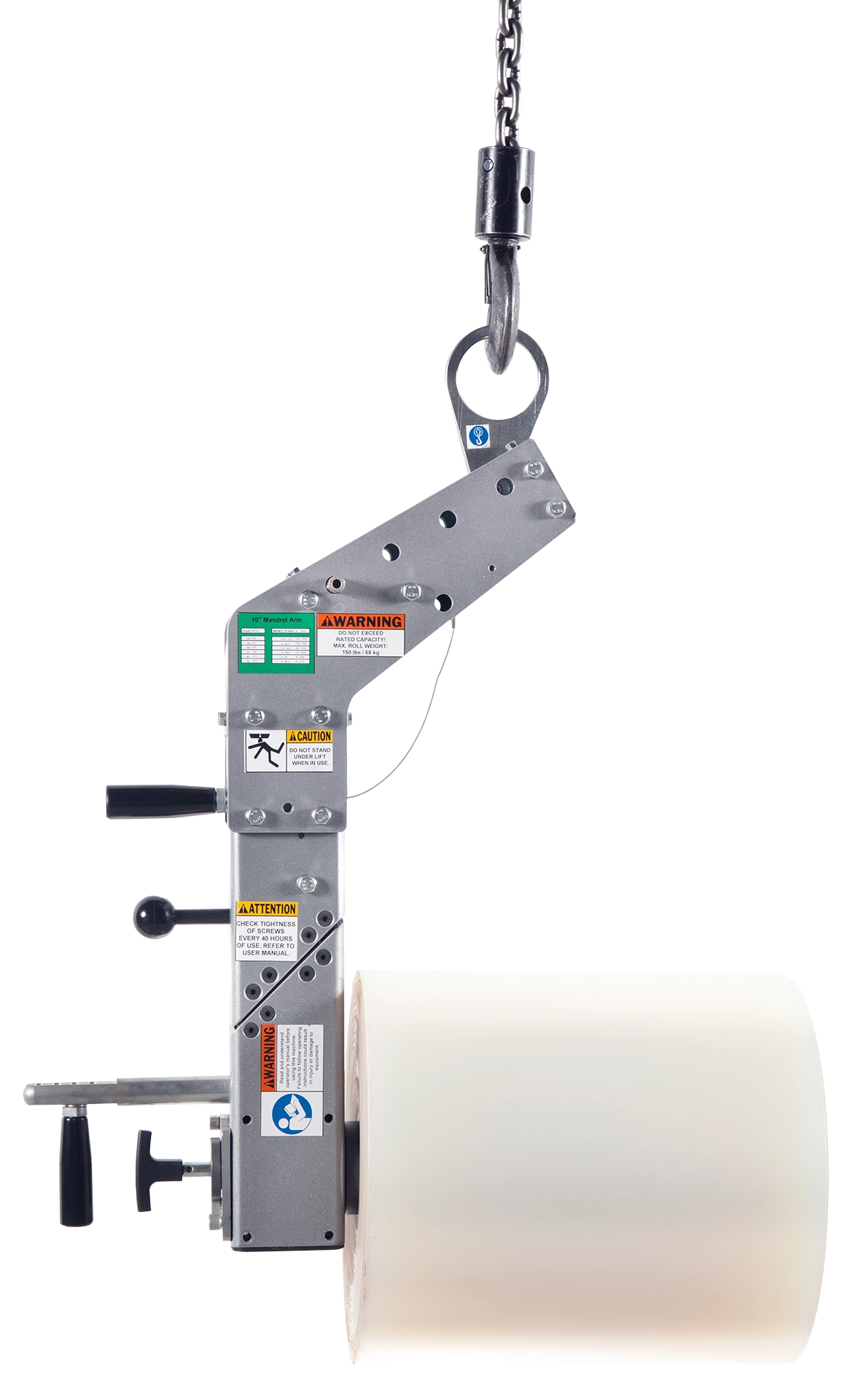

Manual Roll Turner

Double E Group Manual Roll Lift and Turners are easy-to-operate and are used to manually lift and easily rotate rolls between horizontal and vertical axes by their cores. Lift and Turn Roll Handlers utilize existing infrastructure, such as overhead cranes, etc. The Double E Group Lift and Turn Roll Handler simply hooks to the crane and offers a safe, easy-to-use, robust and flexible solution to lift and turn rolls from your pallets or machines regardless of the roll orientation.

Double E Group Manual Roll Turners allow for a weight capacity up to 500 lbs (226 kg).

| Model | Best Use | Load Capacity |

|---|---|---|

MRT-150 |

Best used for lifting of rolled material with low capacity | 150 lbs (68 kg) |

MRT-330 |

Best used for flexible rolled material sizes and for easily changing attachments | 330 lbs (150 kg) |

MRT-500 |

Most often used for larger roll handling applications | 500 lbs (227 kg) |

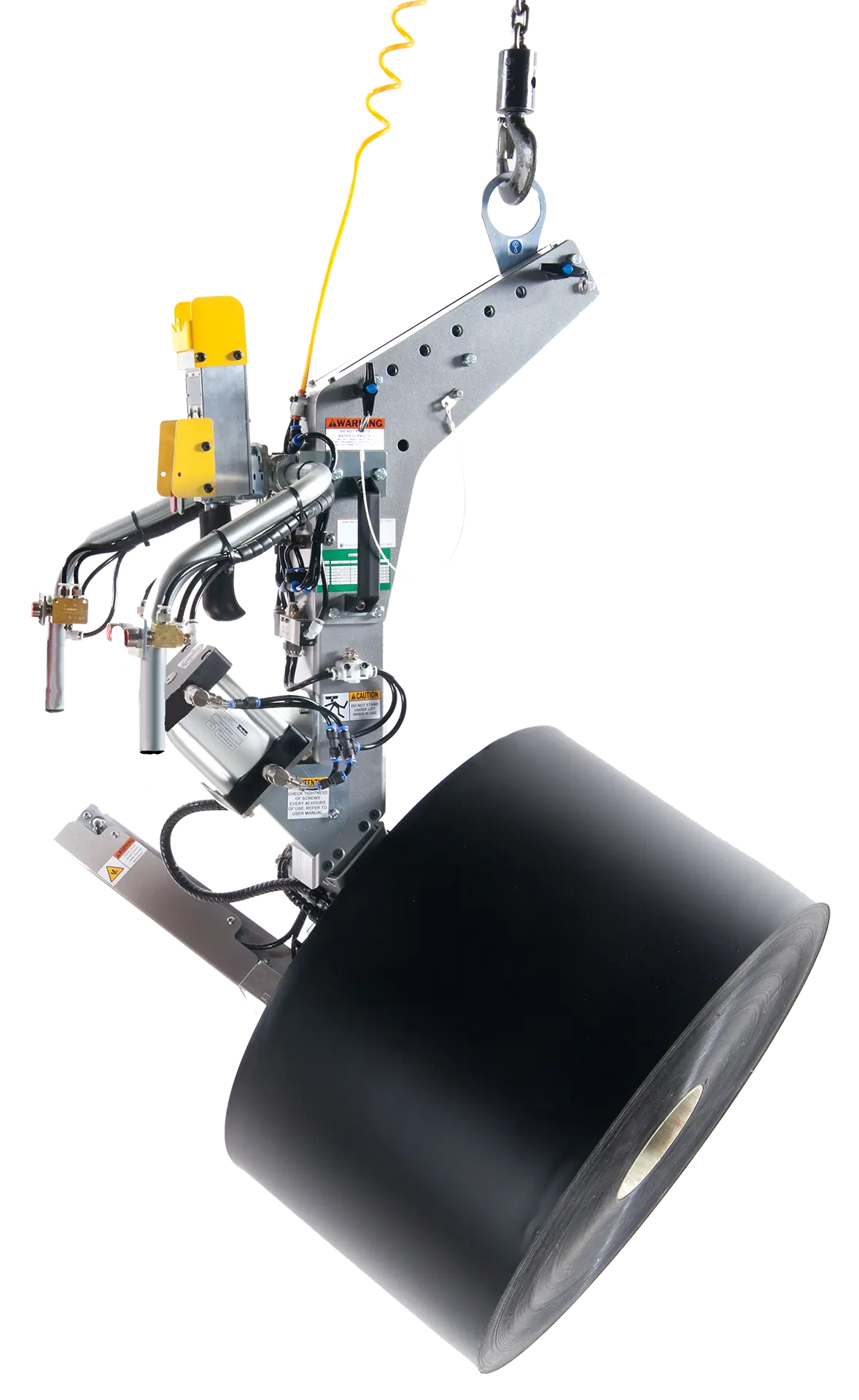

Powered Roll Turner

Powerful and easy-to-operate, Double E Group Powered Roll Turners are available in pneumatic or electric configurations to lift rolled material by its core. They are often chosen when roll weights exceed 330 lbs (150 kg). Double E Group's pneumatic or electric lift and turn assist assures that the roll handling process is safe, quick and easy-to-use.

Double E Group Powered Roll Turners are ideal for applications with narrow, medium weight rolls of consistent width or minimal variation. Roll dimensions and weights are critical for correct sizing of all electric roll turners.

Double E Group Pneumatic and Electric Roll Turners allow for a weight capacity up to 600 lbs. (272 kg).

| Model | Best Use | Load Capacity |

|---|---|---|

PRT-300 |

Best used in high production facilities | 300 lbs (136 kg) |

PRT-500 |

Best used for larger roll handling applications | 500 lbs (227 kg) |

ERT-600 |

Best used for moving rolls to pallet | 600 lbs (272 kg) |

*Capacities are dependent on roll widths and diameters.

OD Clamp Roll Turner

Double E Group OD Roll Turners are available in both pneumatic and electric models. They are an easy-to-use, effective solution to lifting rolls that may telescope if lifted by the core. The OD Clamp Roll Turner is ideal when it is required to lift and turn the roll by the outer diameter instead of the core and when roll weights exceed 330 lbs (150 kg).

Double E Group Pneumatic and Manual OD Clamp Roll Turners allow for a weight capacity up to 500 lbs or (227 kg).

| Model | Best Use | Load Capacity |

|---|---|---|

VODC |

Best used for lifting and turning rolls by their outer diameter |

Custom Capacities |

Which products are best for you?

Back to Top