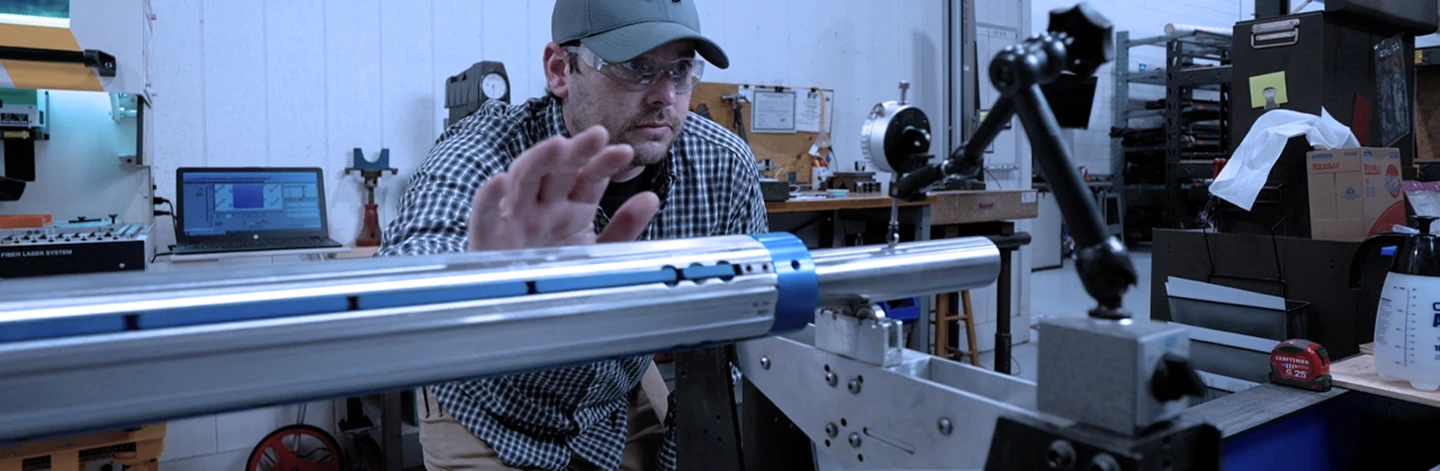

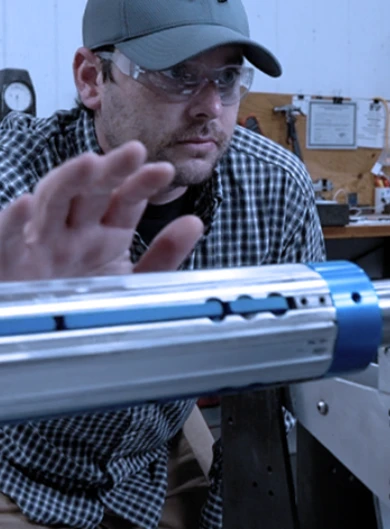

Double E Group carries a wide variety of specialty converting equipment designed for controlling web tension, including controllers, load cells, load cell amplifiers, dead shaft rollers, live shaft rollers, live shaft rollers, laser diameter sensors, dancers, inertia compensation and ultrasonic diameter sensors. From process start to finish, Double E Group web tension control systems are key to ensuring maximum system efficiency and quality of finished products.

What is Web Tension Control?

Web tension control improves uniformity in coating applications and material lamination while decreasing the incidence of rewind defects such as crushed cores, starred rolls, edge curl and telescoped rolls. When web tension is under control it can enable processes to run at higher speeds while reducing scrap, delivering a rapid return on investment that boosts producers’ long term profitability.

Web Tension Control System for the Converting Industry

Since its founding in 1972, Double E Group has supplied web tension control products, services, and support in major industrial markets worldwide. Our product line includes tension controllers, winding and unwinding equipment, core chucks, air shafts, and safety chucks.

Backed by more than 50 years of experience, the Double E Group has played a critical role in the converting industry by providing reliable solutions, quick turnaround and quality service. If you’re looking for a trusted partner for your converting needs,

contact us today and learn more about our lead time, to request a quote, or for any additional questions.