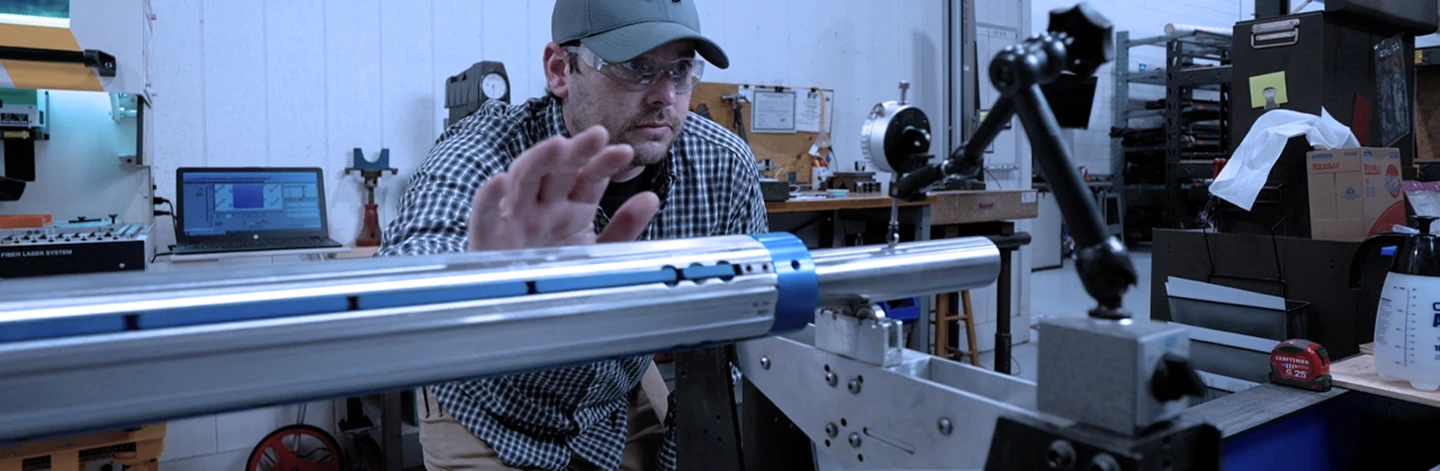

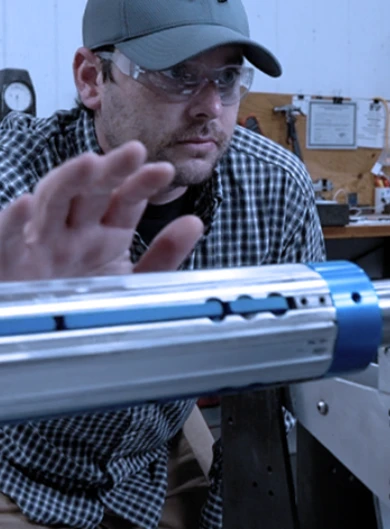

Since its founding in 1972, Double E Group has been a trusted source for quality web handling components for the paper, film and foil web converting/packaging industries. Today, we offer a variety of lightweight, ergonomic core plugs that are ideally suited for a wide range of industrial tissue converters. Advanced composite materials such as carbon fiber-based activation shafts maximize our core plug’s strength and longevity without compromising on efficiency or worker safety.

Double E Group core plugs are components used in the converting industry for securely mounting and supporting cores or core adapters during the unwinding process. These core plugs are crucial elements in maintaining tension and control of materials such as paper and tissue during converting operations. Here are some key points about Double E Group core plugs:

1. Functionality: Double E Group core plugs are engineered to fit into the core or core adapter of a roll of material, providing a stable and secure connection between the core and the winding or unwinding equipment. They ensure proper alignment and support or shifting during the converting process.

2. Construction: Core plugs are typically constructed from durable materials such as steel or aluminum, chosen for their strength and longevity in industrial applications. Our core plugs utilize a carbon fiber central beam that fully supports the core plug. This provides a high-strength, lightweight core plug for operators to safely handle.

3. Compatibility: Double E Group offers a range of core plug sizes and configurations to accommodate different core diameters and types of materials being processed. These core plugs are designed to be compatible with Double E Group's line of shafts and other converting equipment.

4. Versatility: Core plugs are versatile components that can be used in various converting applications, including slitting, unwinding, laminating, and coating. They are essential for ensuring consistent tension and control throughout the converting process, resulting in high-quality finished products.

5. Customization: Depending on specific application requirements, Double E Group may offer customization options for core plugs or specialized designs for unique converting processes. Customization ensures that core plugs meet the unique needs of each converting operation.

Overall, Double E Group core plugs play a critical role in the converting industry by providing reliable support and stability to cores or core adapters during the unwinding processes. They contribute to the efficiency, safety, precision, and quality of converting operations, helping manufacturers produce consistent and high-quality finished products.

Contact us to learn how Double E Group products can improve your business.