In the web converting industry, the process of slitting is an essential step that ensures precision in producing materials such as paper, film, foil, and other flexible substrates. One often-overlooked aspect of this process is the management and collection of slitter trim. Implementing a safe and efficient slitter trim collection system is not only a best practice, but a crucial factor in optimizing operational efficiency, maintaining workplace safety, and reducing environmental impact.

Enhancing Operational Efficiency

A well-designed slitter trim collection system streamlines production processes by ensuring that waste materials are promptly and effectively removed. Without an efficient system, slitter trim can accumulate on the production floor, leading to disruptions, machine downtime, and potential damage to equipment. By integrating high-performance pneumatic or mechanical trim handling solutions, companies can minimize these risks and maintain a steady workflow. This approach not only reduces downtime but also enhances productivity, ensuring that operations remain on schedule.

Improving Workplace Safety

Safety is paramount in any industrial setting, and slitter trim poses unique challenges. Loose trim can create trip hazards for employees or become entangled in machinery, increasing the risk of accidents. By implementing a dedicated trim collection system, businesses can mitigate these risks, ensuring a safer working environment. Modern systems are designed to handle trim at high speeds, collecting it efficiently and depositing it in a controlled manner, which prevents manual intervention and reduces the likelihood of injuries.

Supporting Sustainability Goals

The web converting industry is increasingly focused on sustainability, and effective trim collection plays a significant role in achieving environmental objectives. Trim materials often contain valuable resources that can be recycled or repurposed. For example, paper trim can be recycled into new paper products, while plastic and metal trims can be processed and reused in various applications. By segregating and collecting trim safely, companies not only minimize waste but also contribute to a circular economy, enhancing their environmental credentials.

Reducing Energy and Maintenance Costs

An optimized slitter trim collection system can also lead to significant cost savings. Modern systems are designed to operate with energy efficiency in mind, reducing the overall power consumption of production facilities. Furthermore, by preventing clogs and minimizing wear and tear on machinery, these systems reduce maintenance costs and extend the lifespan of equipment. These savings can have a considerable impact on the bottom line, making a compelling case for investing in advanced trim collection technologies.

Enhancing Product Quality

Effective trim management contributes to consistent product quality by preventing contamination from loose trim. In industries where cleanliness and precision are critical, such as food packaging or medical-grade materials, any foreign particles introduced during production can lead to costly rejections or recalls. A robust trim collection system ensures that production areas remain clean and free of debris, safeguarding product integrity.

Complying with Regulatory Standards

Finally, adopting a safe slitter trim collection system helps companies comply with industry regulations and standards. Occupational safety guidelines often mandate the proper management of waste materials to prevent workplace hazards. Additionally, environmental regulations may require businesses to track and report their waste management practices. A dedicated system simplifies compliance by providing a reliable method of collecting, segregating, and disposing of trim materials.

In conclusion, the benefits of safely collecting slitter trim extend far beyond waste management. From improving efficiency and safety to supporting sustainability and regulatory compliance, an effective trim collection system is a vital component of any modern web converting operation. By prioritizing this aspect of the production process, companies can enhance their operational performance, protect their workforce, and contribute to a more sustainable future.

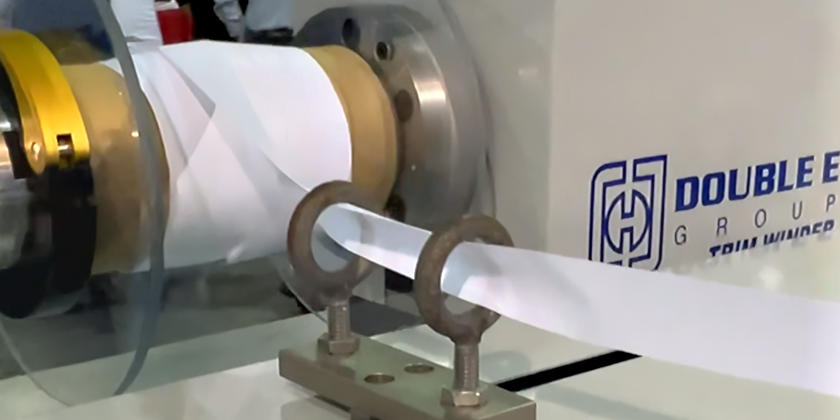

For those looking to take their trim collection to the next level, Double E Group offers innovative trim winders and oscillators designed to improve efficiency, reduce waste, and streamline the slitting process. To discover how Double E Group's solutions can enhance your operations, get in touch with us today for more information or a customized consultation.