PRODUCT FINDER

Which products are best for you?

Web Tension Controllers

Web Tension Control - Closed or Open Loop Configurations

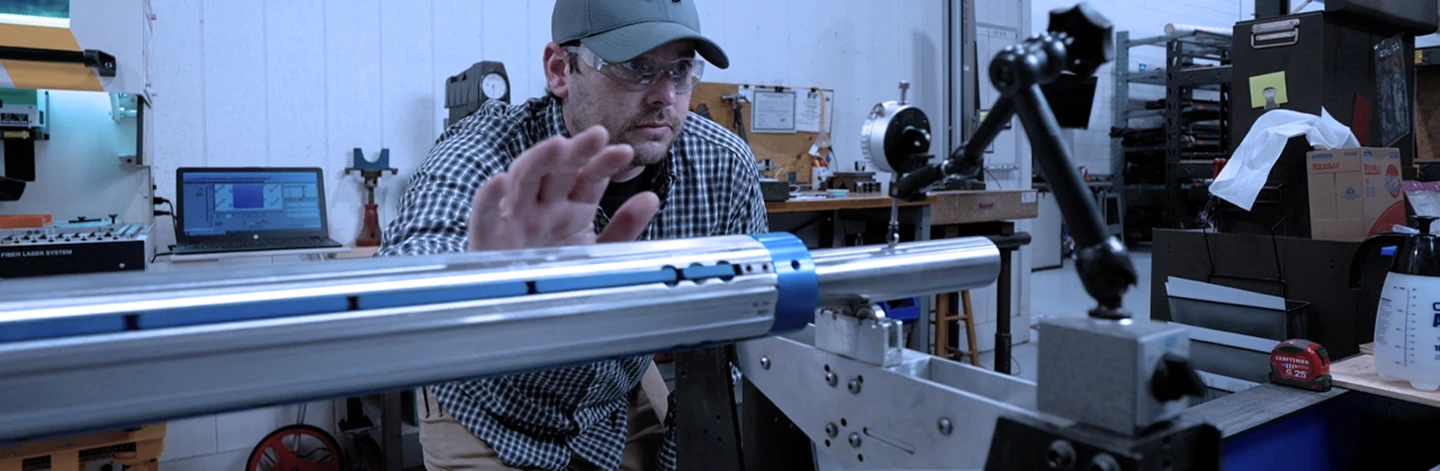

The Double E Group Tension controller is a DIN rail mountable controller that is configurable for multiple uses. The unit can be used stand-alone with color TP HMI or integrated into the user's logic system.

Open Loop Torque Controller

The Double E Group controller uses a distance measurement sensor to monitor roll diameter as the roll unwinds. The controller compares values registered by the diameter sensor with set values then signals the brake or unwind drive to adjust accordingly.

Closed Loop Unwind Controller

The controller uses a dancer roll system or load cells to directly sense web activity. This signal is then compared to a setpoint, and through a PID loop, provides real time feedback to an unwind brake or drive to correct for any variations in tension.

Closed Loop Unwind Controller with Inertia Compensation

The controller operates as described above in closed loop mode, but also uses a diameter input to measure the diameter (and effectively the mass) of the unwinding roll. The roll size value is used to adapt the PID loop as well as the output signal when the roll is accelerating or decelerating for optimal system response at any roll size.

Intermediate Tension Zone Controller

The controller is connected to load cells or a dancer in the middle of a web process between driven nip or pull rolls. The controller PID output adjusts the speed difference between the two drives and is either increased or decreased to correct for variations in tension.

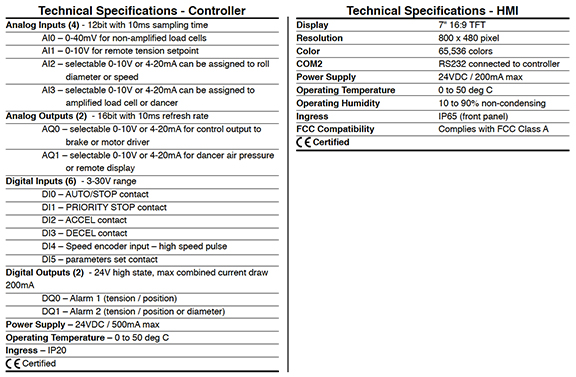

Technical Specifications:

Which products are best for you?

Back to Top