PRODUCT FINDER

Which products are best for you?

Nip / Pull Roll Stations

Nip stations help to precisely set and control line speed. They can easily set up as a material feeder for precise feed lengths. Add nip sections with speed control to establish new tension zones.

Nip stations help to precisely set and control line speed. They can easily set up as a material feeder for precise feed lengths. Add nip sections with speed control to establish new tension zones.

Double E Group Nip Station / Pull Roll Station

The Double E Group manufactures nip roll stations and pull roll stations that you can use to set tension zones or master line speeds. These stations easily synchronize with any section of the production line to help continue production at an even pace.

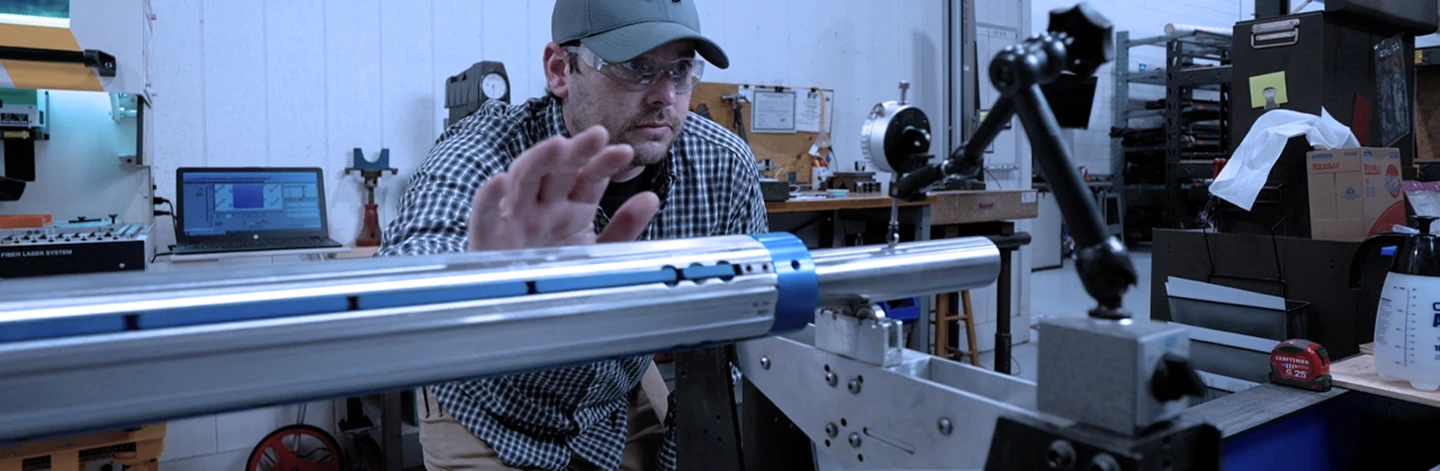

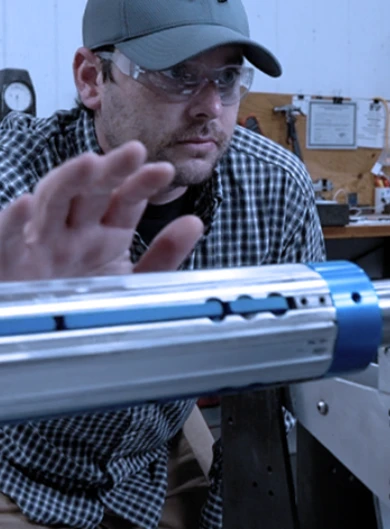

Nip Feed Station used with Die Cutting Machine

This nip station is used with a laser cutting machine that pulls material off of an unwind roll using mechanical grippers and stepper motors. It facilitates using a new material which is very stiff and with high tension. The laser cutting machine was found not strong enough to pull the material off of the roll.

This nip feed station synchronizes with the start/stop signal of the laser cutter to allow automatic feeding of the material off of the unwind stand and onto the table of the laser cutter.

This synchronization allows production to continue at an even pace with no material problems.

Large Format Nip / Pull Stand

The Double E Group engineered this unit with the control system mounted directly to the rolling stand, allowing it to be plugged into the process wherever and whenever it is needed.

Which products are best for you?

Back to Top